The home appliance industry has undergone significant transformations in recent years, driven by advancements in technology and innovative manufacturing processes. Among these, injection molding molds have emerged as a cornerstone in the production of plastic components for various household appliances. Injection molding, a process that involves injecting molten plastic into a mold cavity to form a solid object upon cooling, offers numerous advantages that have revolutionized the way home appliances are designed and manufactured.

Plastic Components in Home Appliances

Home appliances, ranging from refrigerators and washing machines to microwaves and vacuum cleaners, incorporate a significant number of plastic components. These components include housing parts, control panels, handles, buttons, and interior linings, among others. Injection molding molds enable the precise and efficient production of these plastic parts, ensuring that they meet the functional and aesthetic requirements of modern home appliances.

handles, buttons, and interior linings, among others. Injection molding molds enable the precise and efficient production of these plastic parts, ensuring that they meet the functional and aesthetic requirements of modern home appliances.

Advantages of Injection Molding in Home Appliance Manufacturing

Cost-Effectiveness and Efficiency: Injection molding is a highly automated process that allows for the rapid production of large quantities of plastic components. This not only reduces labor costs but also increases production efficiency, enabling manufacturers to meet market demands in a timely manner.

Precision and Consistency: Injection molding molds are precision-engineered to produce components with consistent dimensions and quality. This ensures that plastic parts fit together perfectly, enhancing the overall functionality and reliability of home appliances.

Design Flexibility: Injection molding supports the production of complex shapes and intricate designs. Manufacturers can create plastic components with detailed textures, colors, and finishes, adding to the aesthetic appeal of home appliances.

Material Versatility: Injection molding can work with a wide range of plastic materials, including thermoplastics and thermosets. This versatility allows manufacturers to select the most suitable material for each component based on factors such as durability, weight, and cost.

Sustainability: Injection molding supports the use of recycled plastics, contributing to the sustainability of the home appliance industry. By incorporating recycled materials into the production process, manufacturers can reduce waste and minimize their environmental impact.

Examples of Injection Molded Components in Home Appliances

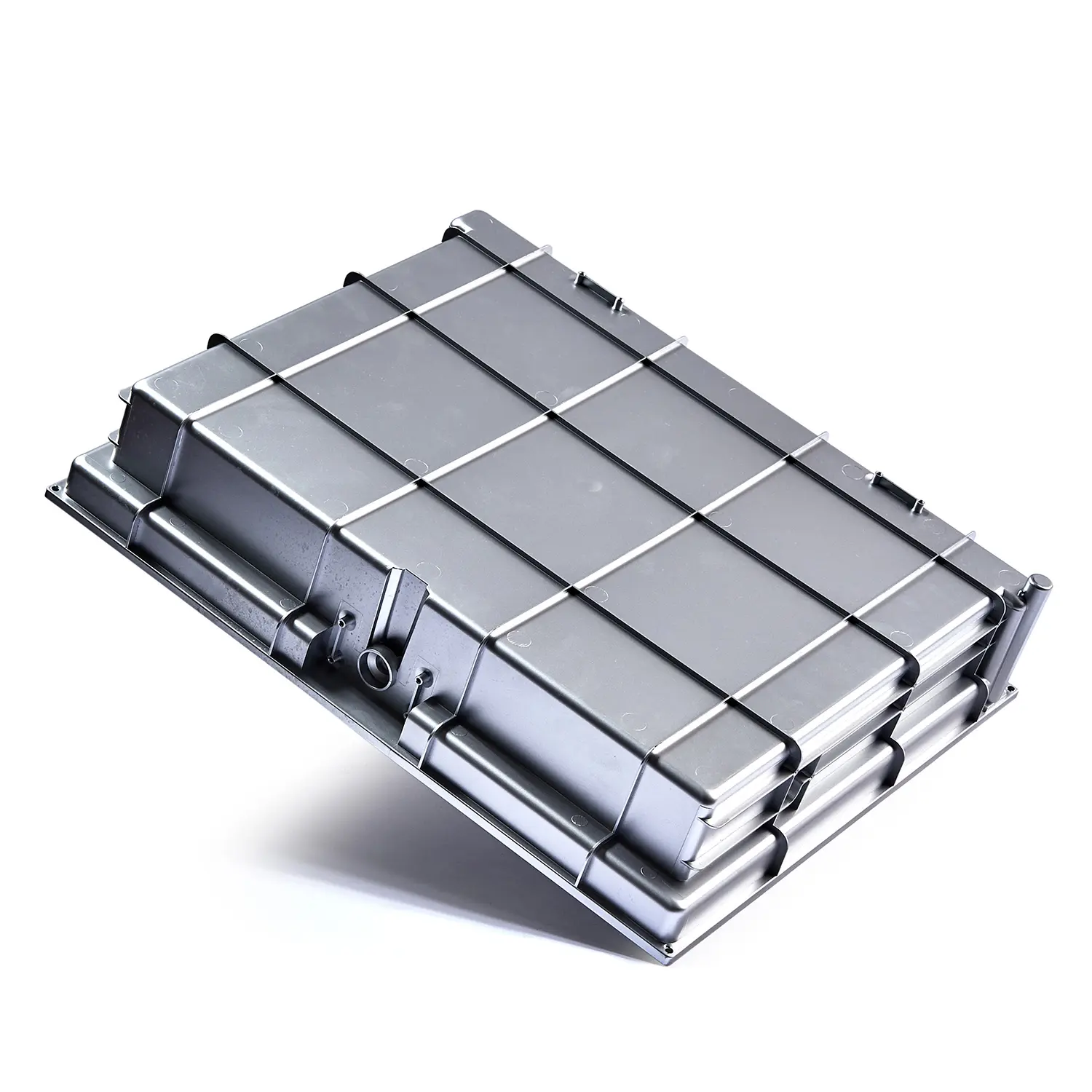

Housing Parts: The exterior shells of refrigerators, washing machines, and other appliances are often injection molded. These parts require a high degree of precision and durability to ensure that the appliances function correctly and look appealing.

Control Panels and Buttons: Injection molding allows for the production of control panels and buttons with intricate designs and clear legends. These components are essential for user interaction and must be both functional and aesthetically pleasing.

Handles and Knobs: Handles and knobs on appliances such as microwaves, ovens, and vacuum cleaners are often injection molded. They require a comfortable grip and ergonomic design to enhance user experience.

Interior Linings and Components: Injection molding is also used to produce interior linings, shelves, and other components within home appliances. These parts must be durable and easy to clean, ensuring that the appliances remain functional and hygienic over time.

Conclusion

Injection molding molds have become indispensable in the home appliance industry, enabling manufacturers to produce high-quality plastic components with precision, efficiency, and cost-effectiveness. As the industry continues to evolve, injection molding will play an increasingly important role in driving innovation and sustainability, contributing to the development of more advanced and user-friendly home appliances. By leveraging the advantages of injection molding, manufacturers can stay competitive in the market and meet the evolving needs of consumers.

Chinese

Chinese English

English Español

Español